Reduced ilmenite

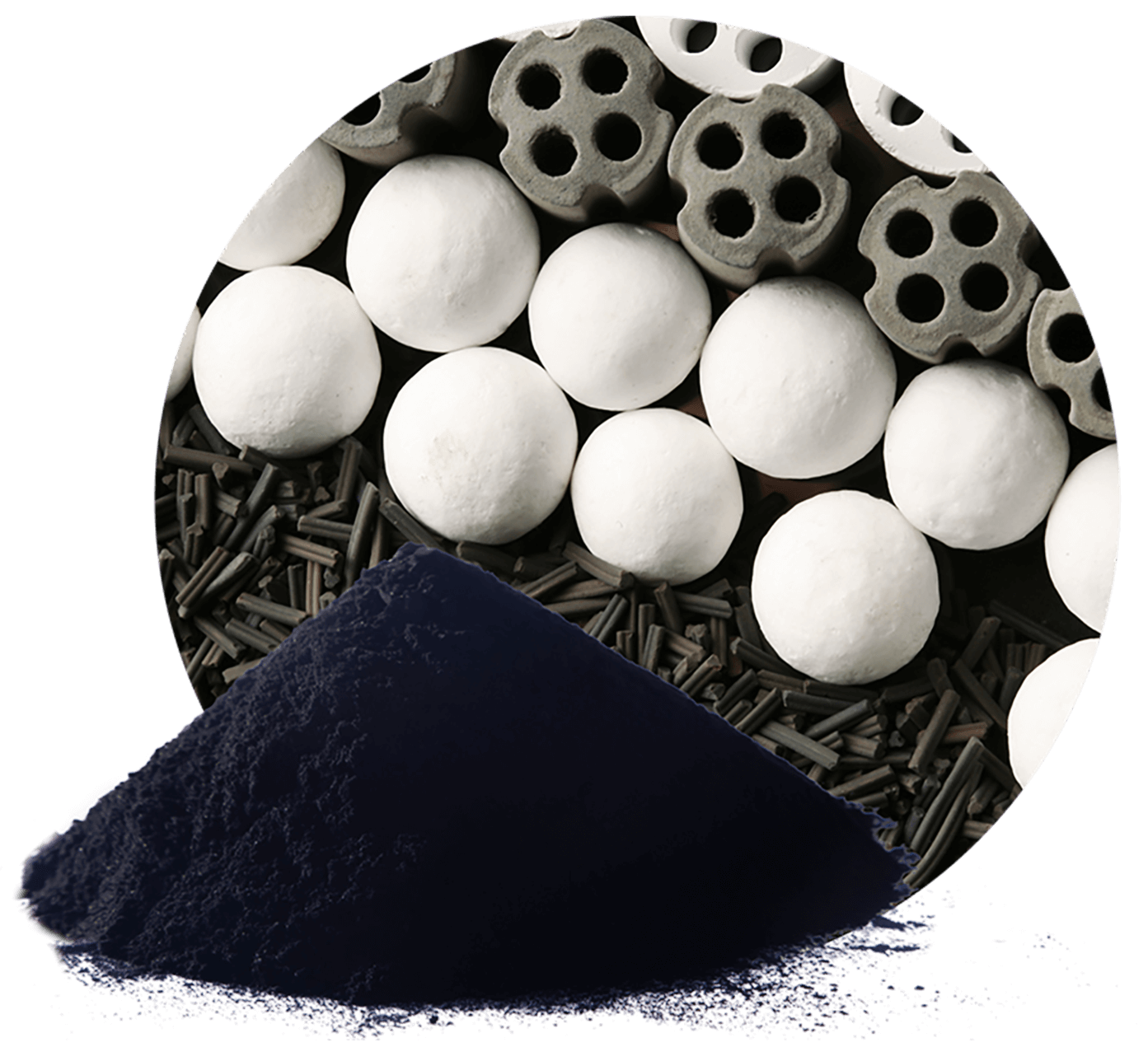

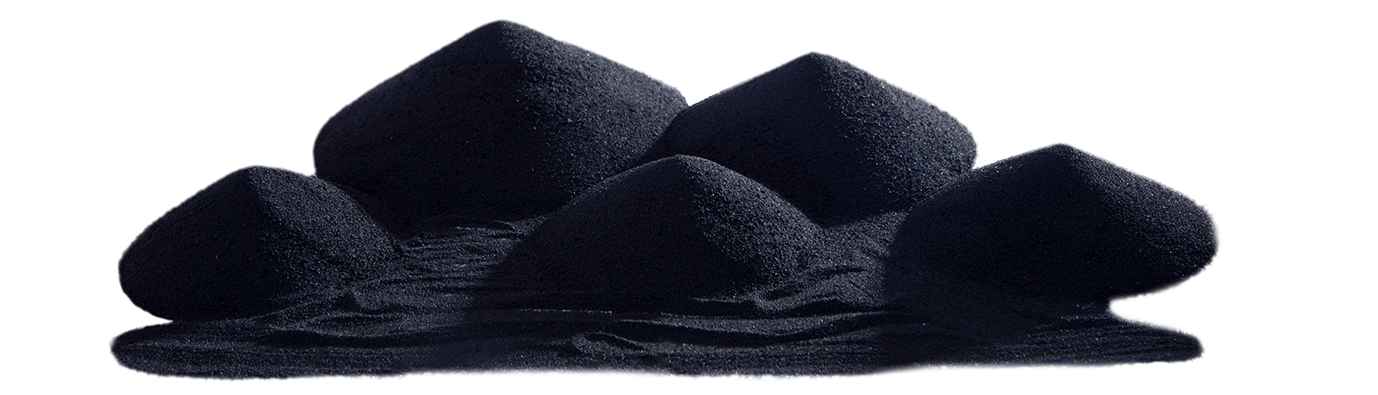

Reduced ilmenite is a dark gray mineral powder, which plays a role in arc stabilization due to its main component being TiO2. Therefore, it can improve the process performance of welding rods. In addition, reduced ilmenite contains nearly 30% elemental iron, which can significantly improve the deposition efficiency of welding materials. It is obtained by preparing ilmenite, reducing agent, and desulfurizing agent into raw materials, adding them to the rotary kiln, and heating them to 1050-1180°C for reduction under a reducing atmosphere maintained at 0-4 mm water column pressure, followed by cooling, sieving, magnetic separation, winnowing, and blending. It has a relative density of 4.0-5.0 and a hardness of 5-5.5. It is iron black or steel gray, with streaks of steel gray or black; when containing hematite inclusions, it appears brown or maroon with a metallic to semi-metallic luster. Reduced ilmenite is opaque with no cleavage.

Details